|

| Vince and his photo skill magic |

Mary drove me to the airport and with some back and forth texting last night we met up with Vince. Since Vince had the day off from school I asked if he wanted to help with the annual, he was excited. We sat on the ramp from 7am to 9:30 waiting on the fog to lift at our destination. The wx at Summit, KEVY was reporting 200 overcast and 1/4 visibility. We checked every half hour and listened as the temp/dew point climbed in unison until about 9:15. We climbed aboard and got the fan turning to let the oil warm up. Vince took the radios and I did the flying, we were off for 58M!

I was high on final as I maneuvered around the "few at 500" that were really sitting at 1000'. The last jet into Wilmington was reporting a 27 knot headwind at 3000 as he was making the RNAV approach to runway one niner. I was high and fast so I went around and re-entered the left down wind and made a nice landing into 58M.

Baring her soul...

We positioned 08Romeo in the hangar and got the annual started. Vince opened up the inspection panels under each wing, main spar and gascolater cover. I removed the tail cone and ELT access panels on each side. The Cecil Aero crew removed the cowling and got started on the power plant checks. I have 30 hours left on my oil changed so it was just a filter removal for inspection. After the oil the plugs were removed and I got to clean them up in the bead blaster. Vince took a break from the screw gun and gave the bead blaster a go, he did very well. Plugs were clean and ready for the anti-seize to be administered. The compression checks were done and they were 77-78-78-77, total engine time was 375 hours.

|

| Plugs looked really good, not much carbon build up |

|

| Vince and the bead blaster experience |

|

| cleaned and ready for installation with fresh anti-seize |

|

Tool used to grease bearings, we used to do this by hand!

Wheel bearings, dust covers and retaining clips

|

| Replacing the baggage door seal |

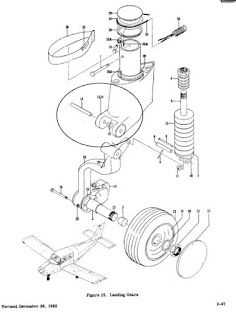

We did find some play in the left main gear during the reinstall (circled), more investigation to follow. It was time to call an end to day one as we all cleaned up and planned for tomorrows fun, er....I mean work.

TUESDAY - ANNUAL DAY 2

Maggie has me up early as she paces the house so I figure I'll get up and work on yesterdays blog and pictures that Vince provided. Mary joins me here in the office with a hot cup of English breakfast tea, my Bride is the best!

Maggie has me up early as she paces the house so I figure I'll get up and work on yesterdays blog and pictures that Vince provided. Mary joins me here in the office with a hot cup of English breakfast tea, my Bride is the best!

|

| cutting open the oil filter for inspection |

|

| main gear knee pin inspection |

After a mandatory stop at dunkin for donuts and hot beverages we headed to the airport. The crew was on a hold with finishing up the gear until we find the status of the knee pin and bushings on each gear. The knee pins revealed little to no deviation but the bushings were obviously shot. Roger made a call for new bushings and they quoted him $600 for each bushing, that's right, EACH bushing. Lets do the simple math, three gear, two bushings each makes it six bushings at six Franklin's each is (body shake) thirty six AMU's. Ok, what was the plan 'B'??

|

| milling the bushing flange |

|

| milling the outside diameter (OD) |

|

| milling the inside diameter (ID) |

|

| Vince giving the metal lathe a go |

THURSDAY - ANNUAL DAY 3

I am headed south with the hope that we can finish up 08Romeo. Still on the list of things to do is engine baffle, front nose gear bushings, close up all the inspection plates, install the baggage door seal and finally clean up and wax.

I make my typical stop for a medium hot tea, black, extra sugar, then get back on the road. Everyone is getting started as I roll in and I jump right into the new seal install. I had previously cleaned the door and all that remained today was coating the door surface with a 3M product specifically called out on the instructions and then add the same product to the seal itself right before I press it into place.

|

| after the glue set on the door I glued the seal about 8 inches at a time |

|

| working my way around the door, making sure the placement was perfect |

|

| finished product! |

Stan was working on the engine baffles and I am thinking that it will be completed tomorrow. It's a long process removing the original rivets and staples, drilling then replacing with new rivets.

I did manage to get most of the plane waxed today and my arms and shoulders are really letting me know. Frank concentrated on the right main gear and nose gear before he got pulled away to work on a straight tail Cessna with some engine issues.

|

| tucked under a wing with my trusty screw gun.... |

|

| wing spar inspection panel |

I got the ok to proceed with installing all the inspection plates that Vince had removed on day one. Everything went back together smoothly except for the wing spar panel. I installed 46 of 48 screws only to find out that the last two, go figure, were missing clip lock nuts.

Yes, I had to remove the screws I put in so I could attach the clip nuts on the metal bracket type brace in order to secure the panel. My arms hate me for doing the screw gun deal twice. With the belly now clean after the install I will get some paint on the trailing edges of the spar panel.

That's about it for day 3. A short list of things to do include a little bit of engine baffle then finish up the nose wheel knee pin and bushing install. Tomorrow will be the run up and leak test then the log book updates.

FRIDAY - ANNUAL DAY 4

Friday starts just like the rest, up early with Maggie then off to Cecil Aero with a dunkin stop for my tea. I thought we would finish up today but Roger decided that he did not like the look of the baffle having to "wrinkle" around the rounded portion of the engine baffle backplate.

|

| left side rounded baffle backplate |

|

| new baffle right side |

|

| new baffle left side |

The shop is doing a really nice job, all new rivets, no more of the staples to be found. I hope this helps my climb out temps that were running a little warmer than I like during the summer. Everything else is complete and 08Romeo will be off the jackstands today ready for her run up.

I left the shop early today since Mary was sick and I wanted to be with her this afternoon. I'll pick up the plane tuesday night or wednesday of next week.

3 comments:

Nice. You can come down to TX and help me with mine. I can fly the darn thing, but with a tool in hand I'm all fingers and thumbs.

Since the wx is warmer I would give it some thought, but can I fly the plane too?

I enjoy getting into the annual, the hands on really is a stress relief for me. I like to see every inch of what makes the sundowner tick, sirt of a comfort factor I guess.

I always enjoy your annual write-ups. Seems like you came out relatively unscathed in terms of the AMUs. Nice work!

Post a Comment