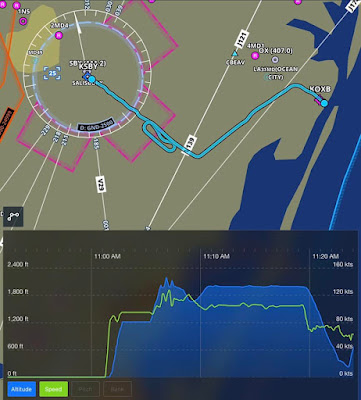

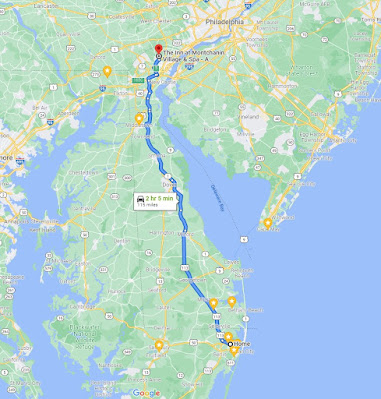

Mary and I made plans to head to Wilmington to visit family and take our recently adopted kittens to our former vet for some surgery. Of course the plan was to fly, but the weather forecast was iffy for departure. My instrument currency has also lapsed as of the end of November. I did make calls, still planning to fly VFR, for hangar space and a rental car. Securing a rental was a no-go, advised to call when you get in and see what we have available. Well, that will not work for us, we needed guaranteed wheels.

Thursday 12.16.21

We were up and out the door by 6am for the two hour drive north. The vet appointment was for 8:30 so we had some float time just in case. Naturally the weather looked doable for a VFR flight, as long as we would have stayed below three thousand five hundred feet. The sky did open up once north of Dover, as it always seems to do.

I forgot about the I-95 construction and hit Wilmington traffic about 7:45ish. Bumper to bumper all through Wilmington, it sucked. Once north of the city I was back up to speed, arriving at the Concord Pike Veterinary Hospital at 8:15. With the boys checked in we headed out for breakfast.

The plan had been made to meet our friends for breakfast at one of our regular stops when we lived in North Wilmington. Angels wasn't crowded since the morning rush had already passed through so we had our choice of seating. Mary Jo and Joe arrived and we picked up conversation like we had seen each other yesterday. Breakfast was excellent and the company even better.

After filling our tummies we headed off for a few items that we needed to pick up. After checking off the list we headed on a tour of my old neighborhood where I grew up, things have sure changed. I also noticed how much the trees and shrubs had matured, more so this trip than any previous trip. The whole north Wilmington area had changed. Gone was the greenhouse and flower shop on Shipley road, now replaced with a sprawling elder care facility. Long gone were the Naamans baseball fields, on Silverside Road, that I had played on, replaced by an office complex many years ago. What was a total shock to the system was the office complex replaced by a new community of stores and apartments, this place was massive! I heard the apartments are renting at $2800 a month...why not buy a house for that monthly cash hit. Route 202 (Concord Pike) had also changed, just in the seven years we've been gone. I was stuck in stupid as we drove along.

I have been struggling to find a new shop to do my annual inspection since the A&P left the shop I was using. The shop manager is still there but I'm not sure how long or if the shop will be there by May of next year. I have decided to have my annual done at New Garden Airport. Mary and I drove up to meet with Jon (Aviation Director) and get 3 Tango Carlie on the May schedule. After discussing rates and availability I locked in our date. I'm glad that's done, one less thing to worry about when it comes to the plane.

We pointed south for Wilmington and to the Inn at Montchanin. Our room was ready so we checked in and had some time to relax before heading out to watch our great nephews Christmas pageant.  |

| Brennan |

|

| Rowan |

|

| Mary and the boys |

The whole group did a great job! Kudos to the teachers, I'm sure it felt like herding cats. The age group was two to four and they all did a wonderful job with the songs and Nativity scene play. Following the play we regrouped and all headed into Wilmington for dinner at Walters Steakhouse. Our reservation was for 8pm and we were seated at 8:15. Mary and I don't typically eat this late so it was a new experience for us. The service was excellent even though it was late into the evening. I had a filet with a twice baked potato and Mary had Prime Rib. We had a short walk back to our SUV, the parking in Wilmington is always an adventure. We headed back to the Inn and called it a night. Tomorrow was going to be another busy day.

Friday 12.17

Rise and shine, it's time to get moving. Mary and I wanted to visit one of her Moms friends that lived in the same condo building. We met with Marge at 10 am and thoroughly enjoyed our visit. Marge is 93, sharp as can be and just a sweet heart. Good memories shared about Mary's Mom and both our families.

Next we headed out to find lunch and bring it with us to visit Mary's Aunt Letti. We all had the turkey with avocado BLT from Panera's. It was fun to sit and chat, catching up on family stuff and enjoying a relaxing break with such a sweet lady. Aunt Letti had her living room redecorated and it looked great, we loved the colors and fabrics she selected. I miss Uncle Reds and his interesting conversations, he is always in our hearts.

Mary and I headed back to our room to freshen up and then headed over to my Sisters home for a visit. My sister Denise and her husband Dave have a beautiful home and it's always comfortable to sit and catch up. We had some Christmas cookies that my sister made from our Moms recipes. Good memories and eats. We certainly always share laughs when we get my sister going, I love visiting her and Dave.

The plan was for the four of us to have dinner at one of our favorites, Culinaria. It's been a long time since we last ate here, maybe before we retired to the beach. Dinner was excellent and so was the service. I enjoyed my go to, center cut beef tenderloin with mushroom sauce, mashed potatoes and asparagus. Mary had the rainbow trout with almond butter, mashed potatoes and asparagus. I would have licked the plate clean but my manners would not allow that. It was a fun evening spending time with my sister and sharing memories along with some good laughs. I miss her being close, but the plane helps cut the distance when we get together. With full tummies we headed back to our room and called it a night.

Saturday 12.18

Mary and I had planned to pick up the kitties at 8:30 but somehow managed to sleep right through that plan. We eventually got motivated and checked out, then headed for coffee and hot tea. Mary picked us up two croissants from Brew HaHA and that served as breakfast for the ride home. The boys were good to go after surgery, and our pockets much lighter after squaring up the bill. It was just over two hours home and then a quick trip to pick up Miss Ziva from boarding. The gangs all home and settled in for the night.

Mary and I had so much fun watching the nephews show and opening the presents we brought them. Time spent with both our families is always treasured, it was a perfect few days up north. Next time I hope we can fly.

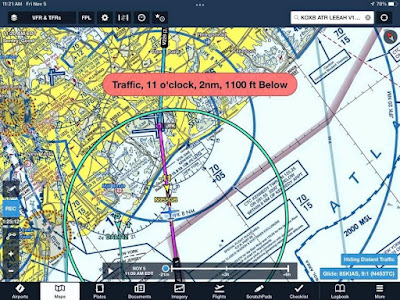

Oh, I almost forgot. A presidential TFR popped up Friday at KILG so we would have been stuck in Wilmington until Monday. Maybe the ground pound was the best choice.